You rely on accurate current measurement for safe and efficient electrical systems. A Manganin copper shunt gives you stable resistance and helps you avoid errors from temperature changes. Many industries use EB shunt designs because they deliver consistent performance. When you choose a Precision Manganin copper Shunt, you notice reliable readings in your metering equipment. A Current Shunt provides the foundation for precise monitoring and control.

Tip: Using the right shunt improves your system’s accuracy and protects your equipment.

Key Takeaways

- Manganin copper shunts provide stable resistance, ensuring accurate current measurements even with temperature changes.

- Using Manganin shunts helps reduce measurement errors, leading to reliable readings in smart meters and other devices.

- Proper installation and maintenance of Manganin shunts are crucial for long-term accuracy and performance.

- Manganin's low temperature coefficient means it maintains consistent resistance, minimizing the need for frequent recalibration.

- Choosing Manganin over other materials like pure copper enhances measurement precision and reduces drift.

Manganin Copper Shunt Fundamentals

Definition and Function in Metering Systems

You use a Manganin copper shunt to measure electric current in metering systems. This device acts as a precise resistor. When current flows through the shunt, it creates a small voltage drop. Your meter reads this voltage and calculates the current. Because the Manganin copper shunt has a low temperature coefficient of resistance, temperature changes do not affect its accuracy much. This feature is important for smart meters and other modern systems. You get reliable readings over long periods, which helps with accurate billing and energy management.

- Manganin shunts give you high precision and low measurement uncertainty.

- Their strong build and resistance to corrosion make them last longer in different environments.

- Consistent performance means your smart meters stay reliable.

Note: In power systems, you need accurate current measurement for fair billing and safe energy distribution. The Manganin copper shunt helps you achieve this by converting high current into a measurable voltage.

Material Composition and Structure

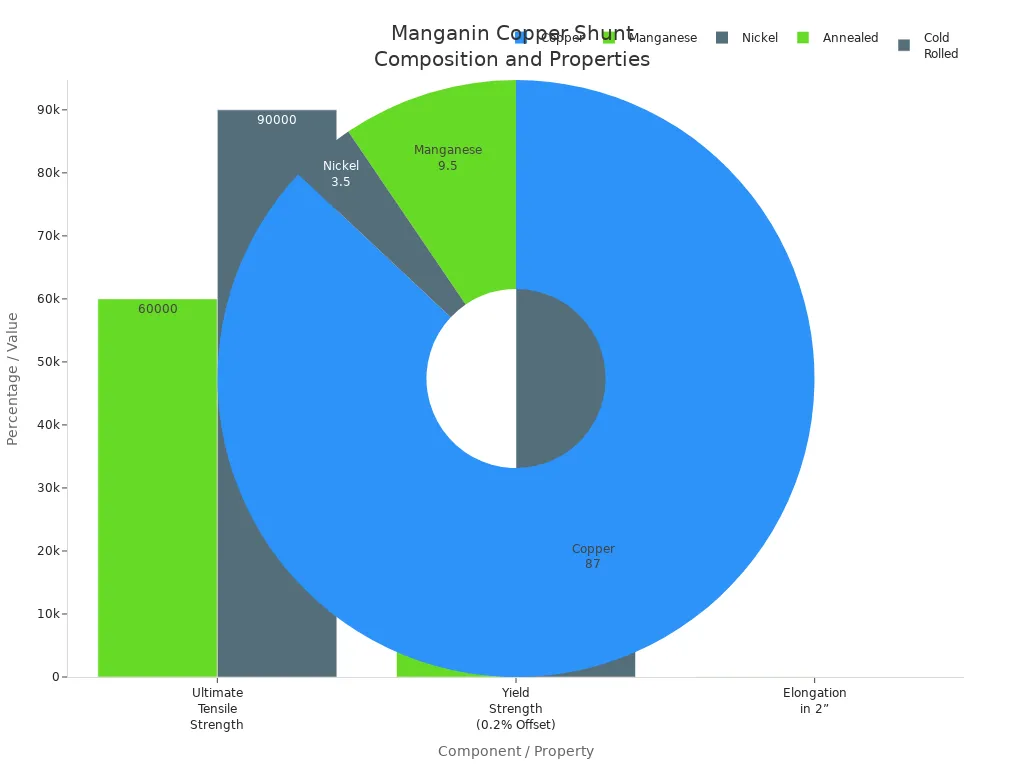

The Manganin copper shunt uses a special alloy. This alloy contains copper, manganese, and nickel. The exact mix gives the shunt its unique properties. You can see the typical composition and mechanical properties in the table below:

| Component | Percentage |

|---|---|

| Copper | 87% |

| Manganese | 9.5% |

| Nickel | 3.5% |

| Mechanical Property | Annealed | Cold Rolled |

|---|---|---|

| Ultimate Tensile Strength | 60,000 PSI | 90,000 PSI |

| Yield Strength (0.2% Offset) | 25,000 PSI | 80,000 PSI |

| Elongation in 2” | 40% | 2% |

This structure gives the shunt both strength and stability. You can trust it to work well even when conditions change.

Importance of Material Selection

Choosing the right material for your shunt is critical. The Manganin copper shunt stands out because:

- It has a low temperature coefficient, so resistance stays steady as temperatures change.

- It offers excellent long-term stability, which means your measurements remain accurate for years.

- The alloy works well in precision instruments and laboratory equipment.

- You need this level of accuracy in applications where even small errors matter.

When you select a Manganin copper shunt, you ensure your metering system delivers precise and reliable results.

Key Properties of Manganin Copper Shunt

Low Temperature Coefficient of Resistance

You want your metering system to stay accurate, even when the temperature changes. The Manganin copper shunt helps you achieve this goal. This special alloy has a low temperature coefficient of resistance. That means its resistance value does not change much when the temperature goes up or down. Copper, which many people use in electrical systems, has a higher temperature coefficient. Its resistance can shift more with heat, causing errors in your measurements.

When you use a Manganin copper shunt, you get stable readings in both hot and cold environments. This stability is important for precision applications, like smart meters and laboratory instruments.

- Manganin shunt resistors maintain a consistent resistance value across a wide temperature range, which is crucial for accurate current measurement.

- They exhibit minimal drift in resistance from -50°C to +200°C, ensuring stability in various environments.

- The low thermal EMF of Manganin helps reduce measurement errors, enhancing the reliability of current readings.

Stable and Predictable Voltage Drop

You need a shunt that gives you a steady voltage drop every time current flows through it. The Manganin copper shunt provides this predictable performance. Your meter reads the voltage drop and calculates the current. If the voltage drop changes because of temperature or material instability, your readings become unreliable.

Here is a table that shows why Manganin stands out:

| Property | Description |

|---|---|

| Low Temperature Coefficient | Manganin's resistance changes minimally with temperature fluctuations, ensuring stability. |

| Stability in Resistance | This stability is crucial for accurate current measurements. |

| Ideal for Precision Applications | Manganin shunts are commonly used in devices requiring high accuracy. |

You can trust your measurements because the voltage drop stays the same, even when the environment changes. This feature helps you avoid costly mistakes and keeps your system running smoothly.

Long-Term Reliability

You want your metering system to last for years without losing accuracy. The Manganin copper shunt offers long-term reliability. Manufacturers test these shunts for stability and durability. You can see how they perform over time in the table below:

| Reliability Metric | Description |

|---|---|

| Long term stability | Stable performance within 20 years |

| Resistant to oxidation | Special material coating on copper protects against oxidation |

| Low temperature confidence | Resistance value change is less than 30ppm from -40℃ to +140℃ |

| Resistant to lightning strike | Passes 3000A 10ms lightning strike test |

Tip: You can install a Manganin copper shunt in harsh environments and expect it to keep working. Its special coating protects against oxidation, and its resistance value stays steady for decades.

You get peace of mind knowing your metering system will deliver accurate results year after year.

Manganin Copper Shunt and Measurement Accuracy

Precise Current Measurement Mechanism

You want your metering system to measure current with high precision. The Manganin copper shunt helps you achieve this goal. It uses a special mechanism that keeps resistance stable, even when the temperature changes. This stability means your readings stay accurate in many conditions.

Take a look at how this works:

| Property | Description |

|---|---|

| Low Resistance Temperature Coefficient | Maintains resistance stability within ±50ppm/℃ across a wide temperature range (-55℃ to +125℃), reducing measurement errors due to temperature fluctuations. |

| Excellent Magnetic Retention Performance | Quickly responds to current changes, stabilizing output voltage even with current fluctuations, ensuring high measurement precision. |

You get fast and reliable voltage readings every time current flows through the shunt. Your meter uses these readings to calculate the exact current. This process helps you avoid errors and keeps your system safe.

Tip: Stable resistance means you can trust your measurements, even if the weather changes or your equipment heats up.

Minimizing Measurement Drift

You want your metering system to stay accurate for years. Measurement drift can cause problems and lead to wrong readings. The Manganin copper shunt helps you minimize drift. It keeps its resistance value steady over time, so you do not need to recalibrate your system often.

Here is a table that shows how it compares to pure copper:

| Property | Manganin | Pure Copper |

|---|---|---|

| Temperature Coefficient of Resistance (TCR) | < 20 ppm/°C | Higher TCR, leading to drift |

| Long-term Stability | High stability, minimal drift | Less stable, requires recalibration |

| Thermal EMF | Extremely low | Higher, can introduce errors |

You see that Manganin copper shunt has a much lower temperature coefficient. This means it does not change much when the temperature goes up or down. You also get very low thermal EMF, so your readings stay true. You spend less time fixing or recalibrating your meters.

Note: When you use a shunt with high stability, you save money and time on maintenance.

Comparison with Other Shunt Materials

You have many choices for shunt materials. Some people use pure copper or other alloys. You need to know how they compare to Manganin copper shunt.

- Pure copper shunts change resistance more when the temperature shifts. This can cause errors in your readings.

- Other alloys may not offer the same long-term stability. You might need to recalibrate them more often.

- Manganin copper shunt gives you steady resistance and low drift. You get accurate measurements for a longer time.

Here is a quick summary:

- Manganin copper shunt: Low temperature coefficient, high stability, minimal drift.

- Pure copper: Higher temperature coefficient, less stability, more drift.

- Other alloys: May offer some benefits, but usually do not match the precision of Manganin copper shunt.

Callout: If you want the best accuracy and reliability, choose a shunt made from Manganin alloy.

You can see why many industries trust Manganin copper shunt for their metering systems. You get precise, stable, and long-lasting performance.

Installation and Operational Best Practices for Manganin Copper Shunt

Proper Mounting and Connection

You need to mount your shunt in the right place to get accurate current measurements. Place the shunt where the current is strongest. This helps your meter read the correct value. Use short, thick wires to connect the shunt to your measuring device. This reduces the chance of errors from extra resistance.

- Always check that your connections are tight.

- Avoid loose wires or poor grounding. These can cause measurement mistakes and even safety problems.

- Make sure the shunt sits firmly on a stable surface.

Tip: Good placement and strong connections help your system stay safe and accurate.

Reducing Lead and Contact Resistance

Lead and contact resistance can lower the accuracy of your readings. You want to keep these as low as possible. Use high-quality wires and connectors. Keep the wires short and thick. This helps the current flow easily and keeps your measurements true.

- Check the resistance between the shunt and your meter often.

- Clean the contacts to remove dust or corrosion.

- Use proper tools to tighten all connections.

A small mistake in wiring can lead to big errors in your readings. Careful setup gives you better results.

Environmental and Maintenance Considerations

Your shunt faces many challenges in its environment. Temperature swings can change resistance. Vibration can cause tiny cracks in the metal. Humidity may lead to rust. Strong magnetic fields can affect your readings.

- Use shunts with sealed or gold-plated terminals to fight corrosion.

- Choose non-magnetic materials to avoid problems from magnetic fields.

- Place the shunt in a spot with little vibration.

Regular maintenance keeps your shunt working well. Here is a table with some important steps:

| Maintenance Protocols | Description |

|---|---|

| Proper Installation | Follow correct steps for mounting and cooling. |

| Maintain Electrical Connections | Check for low resistance and use good measuring devices. |

| Monitor Temperature | Watch for overheating to keep your readings accurate. |

Note: A clean, dry, and stable environment helps your shunt last longer and work better.

Addressing Metering Challenges with Manganin Copper Shunt

Managing Temperature Variations

You often face temperature changes in your metering environment. These changes can affect the accuracy of your current measurements. Manganin shunts help you solve this problem. They have a low temperature coefficient, so their resistance stays almost the same even when the temperature goes up or down. This feature keeps your readings stable and reliable.

When you use a shunt with stable resistivity, you do not need to worry about big temperature swings causing errors.

You can see how well these shunts perform across different temperatures:

| Temperature Range (℃) | Stability |

|---|---|

| -40 to +150 | Stable |

| -60 to +150 | Stable |

This wide range means you can trust your meter in both cold and hot places.

Preventing Corrosion and Oxidation

Corrosion and oxidation can damage your shunt and change its resistance. This can lead to wrong readings. To prevent this, manufacturers use special materials and surface treatments. The table below shows how these methods protect your shunt:

| Method | Description |

|---|---|

| Corrosion Resistance | The alloy material, after surface treatment, resists corrosion even in moisture and salt spray. |

| Oxidation Resistance | Special terminal treatment stops oxidation, keeping performance stable in humid conditions. |

- Shunts with good corrosion resistance last longer.

- You get fewer errors and less need for recalibration.

- If corrosion happens, your meter may lose accuracy.

Tip: Always check for signs of rust or discoloration during maintenance.

Ensuring Calibration Consistency

You want your meter to stay accurate over time. Calibration helps you keep your readings correct. You can use several methods to make sure your shunt stays in top shape:

| Evidence Description | Key Points |

|---|---|

| Precision trimming process | Design and calibration steps help solve measurement problems. |

| Traceable calibration technique | Use a volt-amperometric method for accurate results. |

| NIST measurement service | Follow standard procedures for resistance scaling and calibration. |

- Always use a trusted reference meter when checking your shunt.

- Test your meter in a controlled setting.

- Plan for regular recalibration, especially if your meter works in tough environments.

Note: Regular calibration keeps your system accurate and dependable.

You achieve superior accuracy in electrical metering when you use a Manganin copper shunt. Its stable resistance and exceptional thermal stability help you minimize errors from temperature changes. The alloy’s low temperature coefficient and high corrosion resistance ensure dependable, long-term performance. You meet industry standards like ISO 9001:2015 and UL when you select the right shunt. Remember to choose proper current ratings and install your shunt carefully for the best results.

FAQ

What is a Manganin copper shunt used for?

You use a Manganin copper shunt to measure electric current in metering systems. It helps you get accurate readings by creating a small, stable voltage drop that your meter can read.

How does temperature affect a Manganin copper shunt?

You do not need to worry much about temperature changes. The Manganin alloy keeps resistance steady, so your readings stay accurate in both hot and cold environments.

Why should you choose Manganin over pure copper for shunts?

You get better accuracy with Manganin. Pure copper changes resistance more with temperature. Manganin stays stable, so you avoid errors and get reliable measurements.

How do you maintain a Manganin copper shunt?

You should check connections often and keep the shunt clean. Look for signs of corrosion or damage. Regular maintenance helps your shunt last longer and keeps your readings true.

Can you use a Manganin copper shunt outdoors?

You can use it outdoors if you protect it from moisture and extreme weather. Choose shunts with special coatings for better corrosion resistance. This helps you keep your system working well.

Post time: Aug-29-2025