Selecting the right three phase current transformer requires careful attention to metering or protection needs. Understanding the difference between metering and protection ensures accurate results. Application requirements often vary. For example:

| Application Area | Key Requirements |

|---|---|

| Industrial Motor Loads | High power handling, efficient distribution |

| Commercial Buildings | Central supply for HVAC, elevators, lighting |

| Data Centers | Harmonic suppression, stable voltage for sensitive equipment |

Engineers should consider accuracy, reliability, and safety. Product features, such as those found in Maliotech’s MLTC-2146, can influence metering choices.

Three Phase Current Transformer: Metering vs Protection

Metering CTs: Accuracy and Application

A metering current transformer plays a vital role in energy billing and precise measurement. Utilities and industries rely on metering CTs to ensure fair billing and accurate monitoring of electrical consumption. These devices must deliver high accuracy, especially under normal operating currents. International standards, such as IEC 61869 and ANSI C12.1-2024, define strict accuracy classes for metering. The most common accuracy classes include 0.2, 0.5, and 1. Class 0.2 offers high accuracy for critical billing, while class 0.5 and class 1 serve less demanding applications.

| Accuracy Class | Description |

|---|---|

| Class 0.2 | High precision for metering applications, critical for billing. |

| Class 0.5 | Moderate precision, acceptable for some utility applications. |

| Class 1 | Lower precision, may be used in less critical applications. |

Metering CTs must maintain minimal error to ensure reliable measurement. Overloading a metering CT can reduce accuracy, distort measurement, and even cause financial losses due to incorrect billing. Engineers must match the burden rating to the installation to avoid overheating and premature failures. High accuracy and stable measurement remain the top priorities for metering. The Maliotech MLTC-2146, with its accuracy rating of 0.1/0.2, provides excellent performance for metering, energy meters, and other measurement ct applications.

Protection CTs: Fault Detection and Safety

Protection CTs focus on detecting abnormal currents and ensuring system safety. These devices must respond quickly and reliably during fault conditions. Protection CTs are designed to deliver about 5 amps or less under normal load, but they can withstand up to 20 times the normal current during a fault. Their main job is to trigger relays and disconnect faulty circuits, preventing equipment damage and hazards.

| Category | Common Classes | Primary Use | Error Characteristics |

|---|---|---|---|

| Metering CTs | 0.1, 0.2, 0.5, 1 | Energy billing, precision measurement | Minimal error to ensure fair billing, ideal for normal operating currents. |

| Protection CTs | 5P, 10P, 5P20, 10P20 | Relaying, overcurrent protection | Higher allowable error, but guaranteed to function correctly under high fault currents. |

Protection CTs must not saturate during high fault currents. Features like higher knee point voltages help delay saturation, ensuring reliable relay operation. Differential protection depends on the accuracy of protection CTs. If the measurement ct fails to deliver accurate measurement, the system may trip unnecessarily or fail to trip during a real fault. Protection CTs also integrate safety features such as harmonic restraint and transient response to improve reliability. The Maliotech MLTC-2146 supports protection by providing robust insulation and high withstand voltage, making it suitable for demanding protection applications.

| Type of CT | Response Time | Reliability | Purpose |

|---|---|---|---|

| Protection CTs | Fast | High | Designed for fault detection and relay signaling |

| Metering CTs | Moderate | Moderate | Focused on accurate measurements for billing |

- Protection CTs are built for reliability during fault conditions.

- They must respond quickly to high fault currents without saturating.

- Metering CTs prioritize high accuracy under normal operating conditions.

Combined CTs: Versatility and Space Saving

A three phase current transformer that combines metering and protection functions offers significant advantages. The Maliotech MLTC-2146 serves as an example of a combined current transformer. This device supports both metering and protection, reducing the need for multiple transformers. Its compact design saves space in control panels and switchgear.

Combined CTs provide high accuracy for metering and robust performance for protection. Engineers can use one measurement ct for both energy billing and fault detection. This versatility simplifies installation and maintenance. The MLTC-2146 features standard mounting holes, making it easy to install on circuit boards. Its epoxy encapsulant and flame-retardant case ensure durability and safety in harsh environments.

Tip: When selecting a three phase current transformer, consider combined CTs for projects with limited space or where both metering and protection are required.

A combined measurement ct like the MLTC-2146 supports energy meters, motor control, and AC EV chargers. It delivers high accuracy, reliable measurement, and effective protection in one compact package. This approach streamlines electrical system design and enhances overall safety and performance.

Selecting Current Transformer: Criteria and Mistakes

Key Selection Criteria for Metering CTs

Selecting a metering current transformer for high accuracy billing requires careful attention to several factors. Engineers must first define the goal of the power monitoring project. They should identify the amperage to be monitored, including both minimum and maximum operating currents. The required accuracy plays a major role in choosing between standard and revenue-grade metering ct options. Space constraints in electrical panels often influence the size and type of three phase current transformer selected. Installation flexibility depends on whether CT leads can be extended.

Precision in metering ct selection is essential for accurate billing and energy management. Even small errors in measurement can lead to financial discrepancies. Compliance with IEC 61869-2 ensures that metering ct devices meet global standards for accuracy and regulatory requirements. This standard defines accuracy classes such as 0.1, 0.2, and 0.5, which correspond to maximum permissible errors. Consistency across manufacturers and applications is vital for effective metering and billing.

The Maliotech MLTC-2146 three phase current transformer offers an accuracy class of 0.1/0.2, making it suitable for high accuracy metering. Its compact design addresses space constraints, while its robust insulation and flame-retardant case provide safety and reliability. Engineers should also consider burden ratings, which indicate the total impedance from connected devices. Proper burden management maintains CT accuracy and prevents measurement errors.

Key factors for metering ct selection:

- Project goal and application requirements

- Amperage range for measurement of currents

- Required accuracy class for billing

- Space limitations in installation

- Compliance with IEC 61869-2 and other standards

- Burden rating and installation flexibility

Key Selection Criteria for Protection CTs

Protection ct selection focuses on reliable fault detection and system safety. Engineers must choose a current transformer with the correct ratio and accuracy class for protection applications. The ability to handle high fault currents without saturating is critical. Protection ct devices must respond quickly during fault conditions to ensure differential protection and prevent equipment damage.

Environmental ratings, such as IP65 or IP67, are important for outdoor installations. These ratings protect the protection current transformer from water, moisture, and contaminants, ensuring long-term reliability. The Maliotech MLTC-2146 three phase current transformer features robust insulation resistance and a flame-retardant case, making it suitable for harsh environments.

Accuracy class and burden ratings affect the long-term performance of protection ct devices. Engineers should select a protection ct with a high knee point voltage to delay saturation during fault currents. Compliance with standards such as IEC 61869 and ANSI/IEEE C57.13 ensures reliable operation.

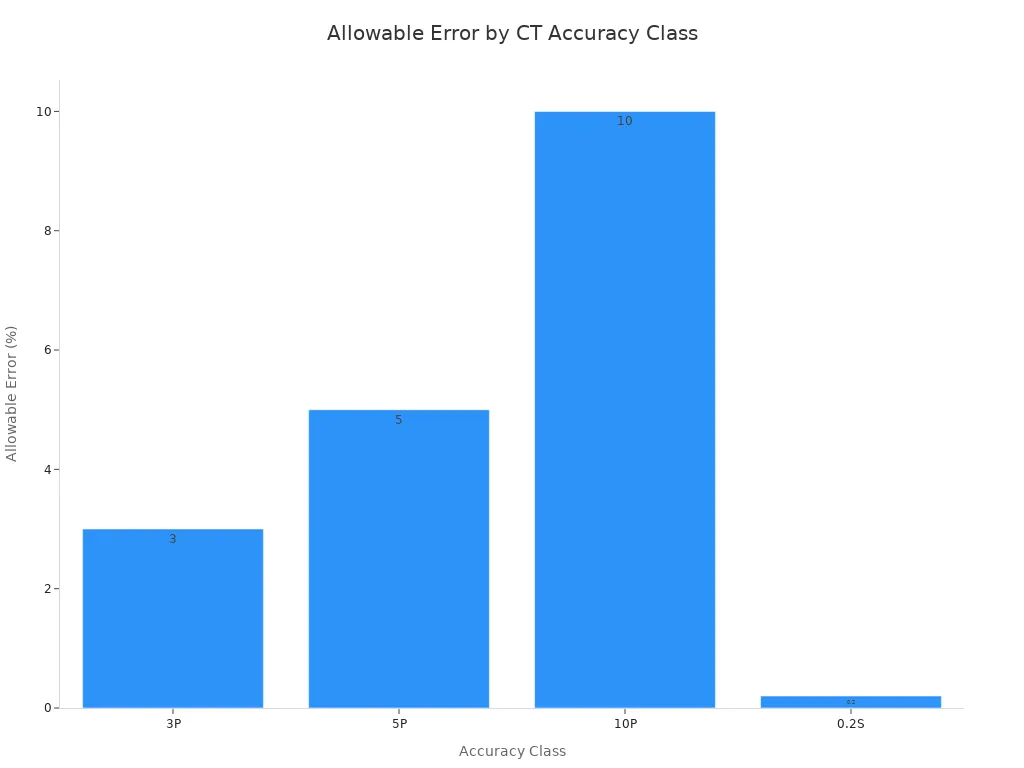

| Accuracy Class | Description | Allowable Error |

|---|---|---|

| 3P | Designed for protection purposes | 3% |

| 5P | Handles high fault currents without saturating | 5% |

| 10P | Focused on protection | 10% |

| 0.2S | Special metering transformer with better low-current performance | 0.2% |

Key factors for protection ct selection:

- Ratio and accuracy class for fault detection

- Environmental ratings for outdoor reliability

- Burden rating and installation practices

- Compliance with IEC and ANSI standards

- Robust insulation and safety features

Common Mistakes to Avoid

Mistakes in selecting a measurement ct can lead to inaccurate readings or compromised protection. Using the wrong type of current transformer for the application often causes system failures. Metering ct devices used for protection may saturate early, resulting in relay malfunctions. Protection ct devices used for metering can cause billing inaccuracies.

CTs may saturate under fault conditions, distorting signals for protection and metering. This can delay relay trips or cause under-billing. Saturated CTs underestimate primary current, leading to financial errors. Engineers must avoid misapplication of CT types to maintain accurate current measurement and reliable protection.

| CT Type | Application Risk | Consequence of Misapplication |

|---|---|---|

| Metering CT | Used in high-speed differential or overcurrent schemes | Premature saturation, widening relay operating time |

| Protection CT | Designed for robustness but can saturate under fault conditions | Under-reaching by distance relays, misoperation by relays |

Other frequent mistakes include ignoring environmental ratings, improper installation, and non-compliance with electrical codes. Engineers should follow recommended practices for verifying CT installation and calibration. Periodic tests, portable calibration equipment, and proper enclosure use help maintain measurement accuracy and protection reliability.

Common mistakes to avoid:

- Using the wrong CT type for metering or protection

- Ignoring environmental ratings for outdoor installations

- Failing to manage burden ratings

- Non-compliance with IEC, ANSI, NEC, or NFPA standards

- Improper installation or calibration procedures

The Maliotech MLTC-2146 three phase current transformer helps users avoid these mistakes by adhering to strict industry standards and offering high accuracy, robust insulation, and easy installation features. Its combined design supports both metering and protection, reducing the risk of misapplication and improving overall system reliability.

Tip: Always match the measurement ct type to the application, verify compliance with standards, and perform regular calibration checks to ensure accurate measurement and reliable protection.

Selecting the right current transformer for metering and protection improves safety and measurement accuracy. Matching CT type to application needs ensures reliable operation. Use the checklist below for quick verification:

| Checklist Item | Description |

|---|---|

| Open Secondary Circuit | Always keep the secondary loop closed during operation to avoid high voltage. |

| Wrong Polarity | Ensure correct polarity (P1/P2, S1/S2) to prevent incorrect readings. |

| Incorrect Burden Match | Match meter impedance with CT specifications to avoid distorted readings. |

| Loose Connections | Double-check torque and contact to prevent intermittent faults. |

Industry standards guide metering selection:

- IEC standards ensure quality and performance.

- ANSI standards support reliability in critical metering applications.

Matching CT type to metering needs enhances system performance. Consult experts or standards when in doubt.

FAQ

What is the difference between a metering ct and a protection ct?

A metering ct provides high accuracy for energy billing and measurement. A protection ct detects fault conditions and supports protection applications by triggering relays during abnormal currents.

How does a protection ct respond to fault conditions?

A protection ct quickly senses fault currents. It activates protection systems to isolate affected circuits, preventing equipment damage and ensuring differential protection during fault events.

Why is high accuracy important in metering and protection?

High accuracy ensures reliable measurement for metering. In protection, accurate measurement ct performance helps detect faults, supports protection ct operation, and maintains system safety during fault conditions.

Post time: Jan-12-2026