You see smart meters everywhere today. The market for smart meters is growing fast, reaching USD 28.2 billion in 2024. Many smart meters use a Current Transformer for smart meter, but alternatives like Rogowski coils, shunt resistors, Hall effect sensors, and MEMS sensors are changing the game. Check out how these options compare:

| Metric | Current Transformers | Smart Meters |

|---|---|---|

| Market Size in 2024 | USD 2.4 billion | USD 28.2 billion |

| Market Size in 2034 | USD 4.4 billion | USD 108.3 billion |

| CAGR | 6.2% | 14.1% |

- Hall effect sensors work well in many industries because they cost less and adapt easily.

- Rogowski coils offer flexible, non-intrusive measurement.

- Shunt resistors give simple, affordable solutions for low-power needs.

You may also find a Current Transformer for energy meter and Current Transformer for electricity meter in older systems, but new solutions offer better accuracy and easier installation.

Key Takeaways

- Explore alternatives to Current Transformers like Rogowski coils, shunt resistors, and Hall effect sensors for better performance in smart meters.

- Consider the advantages of Rogowski coils, such as flexibility and no saturation, making them ideal for high-current applications.

- Shunt resistors offer a cost-effective solution for low-power needs, but ensure they are used in stable temperature environments for accuracy.

- Hall effect sensors provide reliable measurements in noisy settings, making them suitable for industrial applications.

- Evaluate your specific needs and local regulations when choosing a sensor to ensure optimal performance and compliance.

Why Look Beyond the Current Transformer for smart meter?

Limitations of Current Transformers

You may wonder why many experts suggest moving away from the traditional Current Transformer for smart meter. These devices have served for decades, but they come with several drawbacks that can affect your smart meter’s performance.

- Saturation Issues: When a high fault current flows, the core of the transformer can saturate. This causes the device to lose accuracy and give you incorrect readings.

- Burden Sensitivity: If you connect a load that is too large, the transformer’s accuracy drops. You might not get reliable data.

- Temperature Dependence: Extreme heat or cold can change how the transformer works. This can lead to slower operation or even device crashes.

- Wireless Interference: If your system uses wireless current transformers, interference from other devices can cause missed or inaccurate readings.

Note: For accurate measurement, the secondary current must always increase in step with the primary current. If the magnetic core saturates, this balance breaks, and errors appear. Rapid changes in current can push the core into saturation quickly, making the readings unreliable.

Environmental factors also play a big role. Here’s a quick look at how they impact performance:

| Environmental Factor | Impact on Performance |

|---|---|

| Temperature | Slower operation, crashes |

| Humidity | Corrosion, battery leakage |

| Altitude | Less heat dissipation, insulation loss |

Smart Metering Challenges

Smart meters face many challenges when they rely on current transformers. You need to consider these issues before choosing your solution.

- High initial costs for installation and deployment

- Regular calibration and maintenance to keep accuracy

- Large volumes of data that need secure handling

- Risks of unauthorized access and privacy concerns

- Problems with integrating new technology into old systems

- Measurement errors during power surges or voltage spikes

- Power quality monitoring mistakes due to sudden changes

You also need to protect your smart meter from environmental hazards. Outdoor installations need weatherproof cases. Industrial sites may require extra shielding to block electromagnetic interference.

Alternatives to the Current Transformer for smart meter

Rogowski Coils

You may want to consider Rogowski coils as an alternative to the Current Transformer for smart meter. Rogowski coils use Faraday’s law of electromagnetic induction. They do not have an iron core, which makes them flexible and lightweight. You can install them easily, even in tight spaces. Rogowski coils do not saturate, so you can measure a wide range of currents without losing accuracy.

Here is a table that shows how Rogowski coils compare to traditional current transformers:

| Feature | Rogowski Coil | Current Transformer (CT) |

|---|---|---|

| Operating Principle | Faraday’s law of electromagnetic induction | Magnetic induction with an iron core |

| Core | No iron core, flexible | Contains an iron core |

| Saturation | Does not saturate, wide measurement range | Can saturate, limits measurement range |

| Frequency Characteristics | Good frequency response | Limited frequency response |

| Installation | Lightweight, easy to install | Cumbersome, time-consuming installation |

| Measurement Range | 5A to 5000A without saturation | Limited by core saturation |

You get several advantages with Rogowski coils:

- Flexible and easy to install, especially in tight spaces.

- No saturation, so you can monitor high currents accurately.

- Safe to use, which lowers electric shock risks.

- Wide current sensing range, from 5A to 50,000A.

- Good transient response and low harmonic distortion.

However, Rogowski coils also have some disadvantages:

- They cost more than standard current transformers.

- You need specialized electronics to use them.

- They are more complex and may have higher measurement errors in some cases.

- Susceptible to noise and interference, which can affect accuracy.

Tip: Rogowski coils work well in high-power sectors and places where you need flexible installation. You should check if your application needs high accuracy before choosing this option.

Shunt Resistors

Shunt resistors offer a simple and affordable way to measure current in smart meters. You place the shunt resistor in series with the load. The current flowing through the resistor creates a voltage drop. You measure this voltage drop to calculate the current. This method works well for low-power applications.

You need to pay attention to accuracy and safety when using shunt resistors. The material of the resistor affects thermal stability and accuracy. Temperature changes can cause errors, so you must design the system carefully. Using the Kelvin method for layout helps isolate voltage measurement from current flow, which improves accuracy.

Here are some important points for shunt resistor selection:

- Choose resistors with low tolerance (±0.1% or better) for precise measurements.

- Use low-inductance resistors for high-frequency measurements to reduce errors.

- Select resistors with a low temperature coefficient to keep accuracy stable in different temperatures.

Note: Shunt resistors are best for residential smart meters and low-current applications. You should avoid them in high-current or high-voltage environments because they can heat up and lose accuracy.

Hall Effect Sensors

Hall effect sensors give you another option for measuring current in smart meters. These sensors use the Hall effect principle. When current flows through a conductor, it creates a magnetic field. The Hall electrode detects this magnetic flux and generates a small voltage. Special circuits amplify this voltage and transform it into a secondary current that matches the primary current.

Here is a table that explains how Hall effect sensors work:

| Concept | Explanation |

|---|---|

| Magnetic Field | Generated by the primary current and concentrated around the air gap. |

| Hall Electrode | Detects the magnetic flux and generates a small induced voltage. |

| Signal Transformation | The tiny signal is transformed into a secondary current. |

Hall effect sensors have several features:

- They maintain zero magnetic flux in the magnetic circuit using a closed-loop principle.

- Compensation current offsets the effects of the primary current.

- Output circuits process the signal to reflect the primary current accurately.

You benefit from strong resistance to electromagnetic interference with Hall effect sensors. This makes them reliable in noisy environments, such as industrial sites. The output voltage is proportional to the measured current, so you get accurate readings.

Tip: Hall effect sensors work well in places with high electromagnetic noise. You should consider them for smart meters in factories or commercial buildings.

MEMS Sensors

You may see MEMS sensors in many devices today. MEMS stands for Micro-Electro-Mechanical Systems. These sensors combine tiny mechanical parts with electronic circuits. You find them in smartphones, smart watches, and even airplanes. Their small size makes them perfect for smart meters.

MEMS sensors help you measure current with high accuracy. You get fast and reliable readings. Their lightweight design allows you to fit them into tight spaces. You can use them in smart home systems and consumer electronics. MEMS sensors work well for battery protection and power management. They help your smart meter run longer without draining the battery.

Here are some reasons why MEMS sensors stand out in smart meter current sensing:

- You benefit from low power consumption, which keeps your device running longer.

- High sensitivity lets you detect even small changes in current.

- Compact size means you can install them in space-constrained devices.

- MEMS sensors communicate easily with other electronic components.

You also get several advantages when you choose MEMS sensors for your smart meter:

- Miniaturization and integration allow you to use them in small devices.

- Power efficiency helps you save energy and extend battery life.

- Enhanced performance and reliability give you stable readings, even in harsh environments.

Tip: MEMS sensors offer better accuracy and stability than many older technologies. You can rely on them for precise current measurement in modern smart meters.

You may wonder how MEMS sensors compare to the Current Transformer for smart meter. MEMS sensors provide higher resolution and faster response times. You do not need bulky cores or heavy wiring. You can install them quickly and maintain them with less effort. MEMS sensors also support advanced features like device optimization and smart power management.

However, MEMS sensors have some limitations. You may find that they cost more than traditional sensors. Some MEMS sensors may not handle very high currents as well as larger devices. You need to check your application requirements before choosing MEMS sensors.

Here is a quick summary of MEMS sensor features:

| Feature | Benefit for Smart Metering |

|---|---|

| Low Power Consumption | Longer battery life |

| High Sensitivity | Accurate current measurement |

| Compact Size | Fits in small devices |

| Reliable Performance | Stable readings in tough settings |

You can use MEMS sensors in smart meters for homes, offices, and factories. Their flexibility and precision make them a strong choice for next-generation energy monitoring.

Comparing Current Transformer for smart meter Alternatives

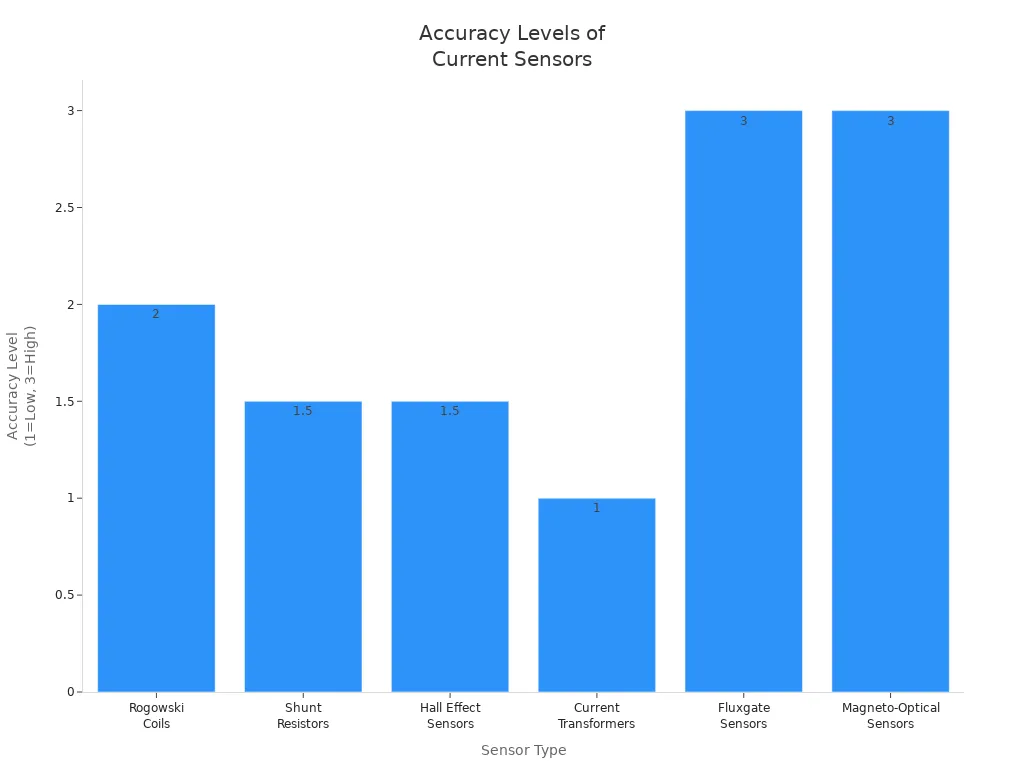

Accuracy

You want your smart meter to give you the most accurate readings. Each sensor type has different accuracy levels. Rogowski coils offer moderate accuracy and work well for high-frequency sensing, but they cannot detect direct currents. Shunt resistors have variable accuracy. They can measure both direct and alternating currents, but temperature changes can affect their performance. Hall effect sensors provide low to moderate accuracy. You need extra circuits to correct for temperature drift. The Current Transformer for smart meter often shows low accuracy because it can saturate and lose precision. Fluxgate and magneto-optical sensors deliver high accuracy, but you may find them too complex and expensive for most smart meter applications.

| Sensor Type | Accuracy Level | Characteristics |

|---|---|---|

| Rogowski Coils | Moderate | Good for high-frequency, cost-effective, cannot detect DC |

| Shunt Resistors | Variable | Measures DC to MHz, affected by temperature |

| Hall Effect Sensors | Low to Moderate | Needs compensation for temperature drift, complex circuitry |

| Current Transformers | Low | Bulky, prone to saturation, accuracy drops |

| Fluxgate Sensors | High | Minimal temperature drift, high accuracy, complex and costly |

| Magneto-Optical Sensors | High | High accuracy, EMI immunity, complex and expensive |

You should know that measurement uncertainty can affect your readings. The resolution of your digital instruments may cause small errors. These errors matter when you want precise data from your smart meter.

Tip: If you need high accuracy, look for sensors with minimal temperature drift and high resolution.

Cost

You need to think about your budget when choosing a sensor. Shunt resistors cost the least. You can use them in simple, low-power smart meters. Rogowski coils cost more than shunt resistors, but you get better performance in high-frequency applications. Hall effect sensors offer a balance between price and features. You pay a moderate price and get good resistance to electromagnetic interference. The Current Transformer for smart meter usually costs more because it is bulky and needs careful installation. Fluxgate and magneto-optical sensors cost the most. You may not need them unless you require top-level accuracy.

- Shunt resistors: Lowest cost, best for basic needs.

- Rogowski coils: Moderate cost, good for flexible installations.

- Hall effect sensors: Moderate cost, reliable in noisy areas.

- Current transformers: Higher cost, older technology.

- Fluxgate and magneto-optical sensors: Highest cost, advanced features.

Note: You should match your sensor choice to your budget and accuracy needs.

Installation

You want installation to be quick and easy. Shunt resistors are simple to install. You place them in series with the load. Rogowski coils are flexible and lightweight. You can wrap them around conductors without disconnecting wires. Hall effect sensors need careful alignment, but you can fit them into tight spaces. The Current Transformer for smart meter is bulky and takes more time to install. You may need extra space and safety measures. Fluxgate and magneto-optical sensors require special setups and expert handling.

| Sensor Type | Installation Difficulty | Notes |

|---|---|---|

| Shunt Resistors | Easy | Simple series connection |

| Rogowski Coils | Easy | Flexible, non-intrusive |

| Hall Effect Sensors | Moderate | Needs alignment, compact design |

| Current Transformers | Difficult | Bulky, needs safety precautions |

| Fluxgate/Magneto-Optical | Difficult | Specialized setup, expert required |

Tip: Choose sensors that fit your space and skill level for installation.

Reliability

You want your smart meter to work reliably for many years. Reliability depends on how well the sensor handles tough conditions. Temperature changes, moisture, and sunlight can damage sensors over time. You need to choose a sensor that resists these problems.

Here is a table showing how environmental factors affect reliability:

| Environmental Factor | Impact on Reliability |

|---|---|

| Temperature Fluctuations | Requires sensors to be designed for high durability |

| Moisture | Needs protective coatings to prevent damage |

| UV Radiation | Demands advanced materials to enhance longevity |

Rogowski coils and MEMS sensors resist temperature swings better than older designs. Shunt resistors need extra protection from moisture. Hall effect sensors last longer if you use them in dry, indoor spaces. You should check if your sensor has coatings or uses strong materials. This helps your smart meter stay accurate and safe.

Tip: Always look for sensors with proven durability and protective features. This keeps your smart meter working even in harsh environments.

Suitability for Smart Metering

You need a sensor that fits your smart meter’s needs. Smart meters do more than measure electricity. They support remote management and tamper detection. You want a sensor that works with these advanced features.

- Smart meters use sensors that measure electricity and support extra functions.

- Data concentrators help many smart meters talk to each other. This lowers costs and makes your system easy to scale.

- Wide-area networks connect smart meters and other devices. These networks use different communication technologies that work well with modern sensors.

Regulatory standards also guide your choice. You must follow rules set by government agencies. These rules cover accuracy, safety, and how devices talk to each other.

- Government regulators set requirements for smart meters.

- Regulations affect how sensors use communication frequencies.

- You need to understand these rules before picking a sensor.

- Industry standards require sensors to meet accuracy and safety goals.

- These standards help you choose the right alternative to the Current Transformer for smart meter.

You should select a sensor that meets all technical and legal requirements. This ensures your smart meter works well and follows the law.

Choosing the Best Current Transformer for smart meter Alternative

Residential Applications

You want your home smart meter to work safely and accurately. When you choose an alternative to the Current Transformer for smart meter, you should look at several key factors:

- Application: Decide what you need to measure. Some homes have solar panels or electric vehicles that change the load.

- Burden: Make sure the sensor can handle the total load for correct readings.

- Instrument Security Factor (ISF): Pick a sensor that stays safe during faults or power surges.

- Short-Time Current Rating: Check if the sensor can survive short bursts of high current.

- Physical Aspects: Think about where you will install the sensor. Look for pollution, dust, or tight spaces.

- Regulation Requirements: Follow your country’s rules for safety and performance.

You may find shunt resistors or Hall effect sensors work well in homes. These options give you good accuracy and easy installation. MEMS sensors also fit small spaces and use little power.

Tip: Always check your local standards before you install a new sensor.

Commercial Applications

In offices, stores, or apartment buildings, you need sensors that handle more power and more complex loads. You want a solution that balances cost, accuracy, and easy maintenance. Rogowski coils can help you measure large currents without heavy equipment. Hall effect sensors resist electrical noise, which is common in busy buildings. MEMS sensors fit into modern, compact smart meters.

You should also think about future needs. Choose a sensor that supports remote monitoring and can connect with building management systems. This helps you track energy use and spot problems early.

Note: Commercial smart meters often need sensors that can handle both steady and changing loads.

Industrial Applications

Factories and plants need tough sensors. You must pick a sensor that works in harsh conditions and meets strict rules. Use this table to guide your choice:

| Criteria | Description |

|---|---|

| Purpose | Decide if you need measurement for billing or protection from overloads. |

| Electrical Parameters | Check the highest current and the standard output (1A or 5A). |

| Environmental Conditions | Think about heat, humidity, corrosion, and altitude. |

| Physical Characteristics | Make sure the sensor fits your equipment and space. |

| Compliance with Standards | Confirm the sensor meets all safety and operation rules in your area. |

You may want Rogowski coils for flexible installation or MEMS sensors for fast, accurate data. Always match the sensor to your plant’s needs and local regulations.

Tip: In industrial settings, reliability and safety matter most. Choose sensors built for tough jobs.

You have many choices beyond the Current Transformer for smart meter. The table below shows how Rogowski coils, shunt resistors, and Hall effect sensors compare for smart meter applications:

| Sensor Type | Advantages | Limitations |

|---|---|---|

| Hall Effect Sensors | Non-intrusive, isolation | Saturation, temperature |

| Shunt Resistors | High accuracy, low cost | Intrusive, limited frequency |

| Rogowski Coils | Flexible, wide frequency | Integration complexity |

Before you select a solution, review these steps:

- Check voltage ratings and mounting stability.

- Plan for safe shutdowns during installation.

- Confirm output compatibility and cabling.

- Look for built-in protection.

Avoid mistakes like poor meter access, cramped installation spaces, and missed manual readings. Assess your needs carefully to ensure reliable smart meter performance.

FAQ

What is the safest alternative to a current transformer for home use?

You can choose MEMS sensors for your home. MEMS sensors use very little power and fit in small spaces. They do not get hot or cause electric shocks. You get safe and reliable readings.

Can Rogowski coils measure direct current (DC)?

No, Rogowski coils cannot measure direct current. They only work with alternating current (AC). If you need to measure DC, you should use shunt resistors or Hall effect sensors.

How do shunt resistors affect smart meter accuracy?

Shunt resistors give you high accuracy for low currents. Temperature changes can cause errors. You should pick resistors with low temperature coefficients to keep your readings stable.

Which sensor works best in noisy industrial environments?

Hall effect sensors work best in places with lots of electrical noise. You get strong resistance to interference. Your smart meter stays accurate even in busy factories.

Do new sensors cost more than traditional current transformers?

You may pay more for MEMS sensors or Rogowski coils. Shunt resistors and Hall effect sensors often cost less. You should match your budget to your needs for accuracy and reliability.

Post time: Aug-14-2025