Selecting the right power transformer can feel confusing. Many people face challenges like picking the wrong transformer type, underestimating load needs, or forgetting about safety. You may also overlook important factors such as local standards, maintenance, or even supplier reliability. Some transformers, like a pulse transformer, work best for special signals, while a low frequency transformer or a high frequency transformer fits certain power systems. Matching the transformer to your exact needs helps you avoid costly mistakes and ensures safe, smooth operation.

Key Takeaways

- Choosing the right power transformer is crucial for safe and efficient operation. A wrong choice can lead to equipment damage and increased costs.

- Always calculate your load requirements accurately. Consider factors like voltage, current, and future growth to avoid overloads.

- Understand the difference between single-phase and three-phase transformers. Select based on your power needs and application type.

- Plan for environmental conditions when installing a transformer. High temperatures and humidity can affect performance and lifespan.

- Follow safety standards and regulations during installation. Compliance helps prevent accidents and ensures reliable operation.

Power Transformer Basics

What Is a Power Transformer?

A power transformer is a device that helps move electrical energy from one circuit to another. You use it to change voltage levels, making electricity safe and useful for homes, schools, and factories. When you look inside a power transformer, you find several important parts:

- Core: This part guides the magnetic field and helps reduce energy loss.

- Windings: These are coils made from copper or aluminum. They help change the voltage from high to low or low to high.

- Insulation: This keeps the windings safe from electrical problems. It uses special paper and oil to cool and protect the parts.

- Tap Changer: This part lets you adjust the voltage so you get the right amount of power.

- Standards and Regulations: Groups like IEEE and IEC make rules to keep transformers safe and reliable.

You see power transformers in many places, from big power plants to small buildings. They help keep your lights on and your devices running.

Why Correct Power Transformer Selection Matters

Choosing the right power transformer is very important. If you pick the wrong one, you can face many problems:

- You might not get enough power for your equipment.

- The voltage could become unstable, causing lights to flicker or machines to stop.

- You could lose energy, which means higher bills.

- Your equipment might break sooner than expected.

- Safety risks can increase, putting people and property in danger.

When you select the correct power transformer, you help your system run smoothly and safely. You also save money and avoid trouble in the future.

Identifying Power Transformer Requirements

Determining Load Type and Size

You need to know your load type and size before you choose a transformer. This step helps you avoid problems like overloads or power loss. The load can be anything from lights in your home to machines in a factory. Each type of load needs a different amount of power.

Here are the main factors you should consider when figuring out your load type and size:

- Load demand: Find out how much power your equipment needs. You can do this by checking the current and voltage requirements.

- Voltage levels: Make sure the transformer’s input and output voltages match your system.

- Power factor: If your equipment has a low power factor, it will need more current. This means you may need a larger transformer.

- Efficiency: High-efficiency transformers cost more and are bigger, but they waste less energy.

- Overload capacity: Your transformer should handle short bursts of extra power without damage.

Tip: Always plan for a little extra capacity. This helps if you add more equipment later or if your load changes.

Engineers use a few steps to estimate the right size for your transformer:

- Determine the load voltage and the current for each phase.

- Multiply the voltage by the current, then divide by 1,000 to get kilowatts (kW).

- Divide the kW by 0.8 to adjust for the typical power factor.

- Add about 20% to your total for future growth.

- Include a start factor, usually 125%, to handle high starting currents.

If your location has special conditions, like high altitude or hot weather, you may need to adjust the transformer’s rating. This process is called de-rating.

Understanding Voltage and Current Needs

You must match the voltage and current of your transformer to your system. If you get this wrong, your equipment may not work or could get damaged. The voltage and current also affect the size, cost, and safety of your transformer.

- Nominal Voltage: This is the main voltage your transformer will handle. It must match your supply and your load.

- Voltage Fluctuations: Transformers help keep the voltage steady, even if your supply changes.

- High Voltage (HV) and Low Voltage (LV): High voltage is good for sending power over long distances. Low voltage is safer for homes and small buildings.

- Insulation Design: Higher voltages need better insulation to keep the transformer safe.

- Cooling Method: Bigger transformers or those with higher currents may need special cooling.

- Core Size: Higher voltage and current mean a bigger core and a larger transformer.

- Transformer Rating: The voltage and current decide how much power your transformer can handle.

- Size and Cost: Higher ratings mean bigger and more expensive transformers.

- Compatibility: Always check that your transformer matches your supply and your load.

Here is a table showing standard voltage and current ranges for transformers in commercial buildings:

| Transformer Type | Voltage Range | Current Range |

|---|---|---|

| Single-phase | 600 V and below | 1-333 kVA |

| Three-phase | 600 V and below | 3-500 kVA |

You may also see these voltage levels:

- Low Voltage: Up to 1kV

- Medium Voltage: 1kV – 69kV

- High Voltage: 69kV – 230kV

- Extra High Voltage (EHV): 230kV – 400kV

- Ultra High Voltage (UHV): Above 400kV

Single-Phase vs. Three-Phase Power Transformer

You need to choose between single-phase and three-phase transformers. Your choice depends on your power needs and the type of load you have.

| Feature | Three-Phase Transformer | Single-Phase Transformer |

|---|---|---|

| Cost | Higher initial cost, better for large systems | Lower cost, good for small setups |

| Efficiency | Very efficient, less power loss | Less efficient for big loads |

| Power Handling | Handles heavy-duty and large-scale loads | Best for small power needs |

| Maintenance | Needs more care and skill | Easier to maintain |

| Size | Larger and heavier | Smaller and lighter |

| Applications | Used in industry and big buildings | Used in homes and small businesses |

| Complexity | More complex design | Simple design |

| Power Delivery | Steady and balanced | More ups and downs in power |

| Load Distribution | Shares load across phases, less risk of overheating | Load can be unbalanced |

- Advantages of Single-Phase Transformers:

- Lower cost and simple design

- Easy to install and maintain

- Good for small loads

- Disadvantages of Single-Phase Transformers:

- Not efficient for big loads

- Power can fluctuate more

- Limited to small applications

If you run a factory or a large building, you should pick a three-phase transformer. For homes or small shops, a single-phase transformer works well.

Calculating Power Transformer kVA Rating

How to Calculate kVA for Your Power Transformer

You need to know the right kVA rating before you choose a transformer. The kVA rating tells you how much power your transformer can handle. If you pick the wrong size, your equipment may not work well or could get damaged.

To find the kVA rating, you must know the voltage and the current your system needs. The formula changes a little for single-phase and three-phase systems.

- For single-phase transformers, use this formula:

kVA = (Voltage × Current) / 1,000 - For three-phase transformers, use this formula:

kVA = (√3 × Voltage × Current) / 1,000

Tip: Always check the voltage and current values for your biggest load. This helps you avoid overloads.

You should also plan for the future. Estimate your maximum load and add a safety margin of 10% to 25%. This extra space lets you add more equipment later without needing a new transformer.

Here are some best practices to follow:

- Use load calculators or electrical software for large projects.

- Ask a professional engineer for help with important or complex systems.

- Always size your transformer for the highest demand plus a safety margin.

Common mistakes can lead to problems. Watch out for these errors:

- Ignoring the power factor.

- Underestimating the peak load.

- Forgetting about future growth.

- Not thinking about the environment, like high temperatures.

Example kVA Calculation

Let’s look at a real example. Imagine you run a small business and need to pick a transformer. You have both single-phase and three-phase equipment. Here is how you would do the math:

| Calculation Type | Formula | Example Calculation | Result |

|---|---|---|---|

| Single-Phase kVA | Volts × Amps / 1,000 | 120 × 50 / 1,000 = 6,000 / 1,000 | 6 kVA |

| Three-Phase kVA | Volts × Amps × √3 / 1,000 | 240 × 60 × 1.732 / 1,000 = 24,940 / 1,000 | 24.94 kVA |

| Future Capacity | Add 20% to calculated kVA | 24.94 kVA + 4.99 = 29.93 kVA | 29.93 kVA |

| Standard Sizes | Round to nearest standard size | 29.93 kVA rounds up to 30 kVA | 30 kVA |

Note: Always round up to the next standard size. This keeps your system safe and ready for more load.

When you follow these steps, you make sure your power transformer fits your needs today and tomorrow. You avoid overloads, keep your equipment safe, and save money in the long run.

Environmental and Application Factors for Power Transformer

Installation Location Considerations

You need to think about where you will install your transformer. The environment can change how well your transformer works and how long it lasts. High temperatures can make insulation age faster. Humidity can cause insulation breakdown and corrosion. If you install a transformer at a high altitude, cooling becomes harder and the air does not protect against electrical problems as well.

Here is a table that shows how different environmental factors affect transformers:

| Environmental Factor | Effect on Transformers | Example Case |

|---|---|---|

| Ambient Temperature | Speeds up insulation aging; cold reduces oil flow | Desert or arctic areas |

| Humidity & Moisture | Causes insulation breakdown and corrosion | Tropical climates |

| Altitude | Lowers cooling and dielectric strength | Mountain installations |

You should always check the local climate before you choose a transformer. If you plan to install in a place with extreme weather, pick a model designed for those conditions.

Safety and Compliance Standards

Safety must come first when you install a transformer. You need to follow rules that protect people and property. In the United States, you must meet standards like the National Electrical Code (NEC), Underwriters Laboratories (UL), and IEEE guidelines. These standards cover wiring, overcurrent protection, clearances, and safe operation.

| Standard | Description |

|---|---|

| National Electrical Code (NEC) | Sets rules for installation, wiring, and safety in hazardous places |

| Underwriters Laboratories (UL) | Makes sure transformers meet safety performance standards |

| IEEE Standards (C57 series) | Gives guidelines for design, testing, and maintenance of transformers |

You also need to think about heat, noise, chemical leaks, fire risks, and electromagnetic disturbance. Following these standards helps you avoid accidents and keeps your system running safely.

Special Application Needs

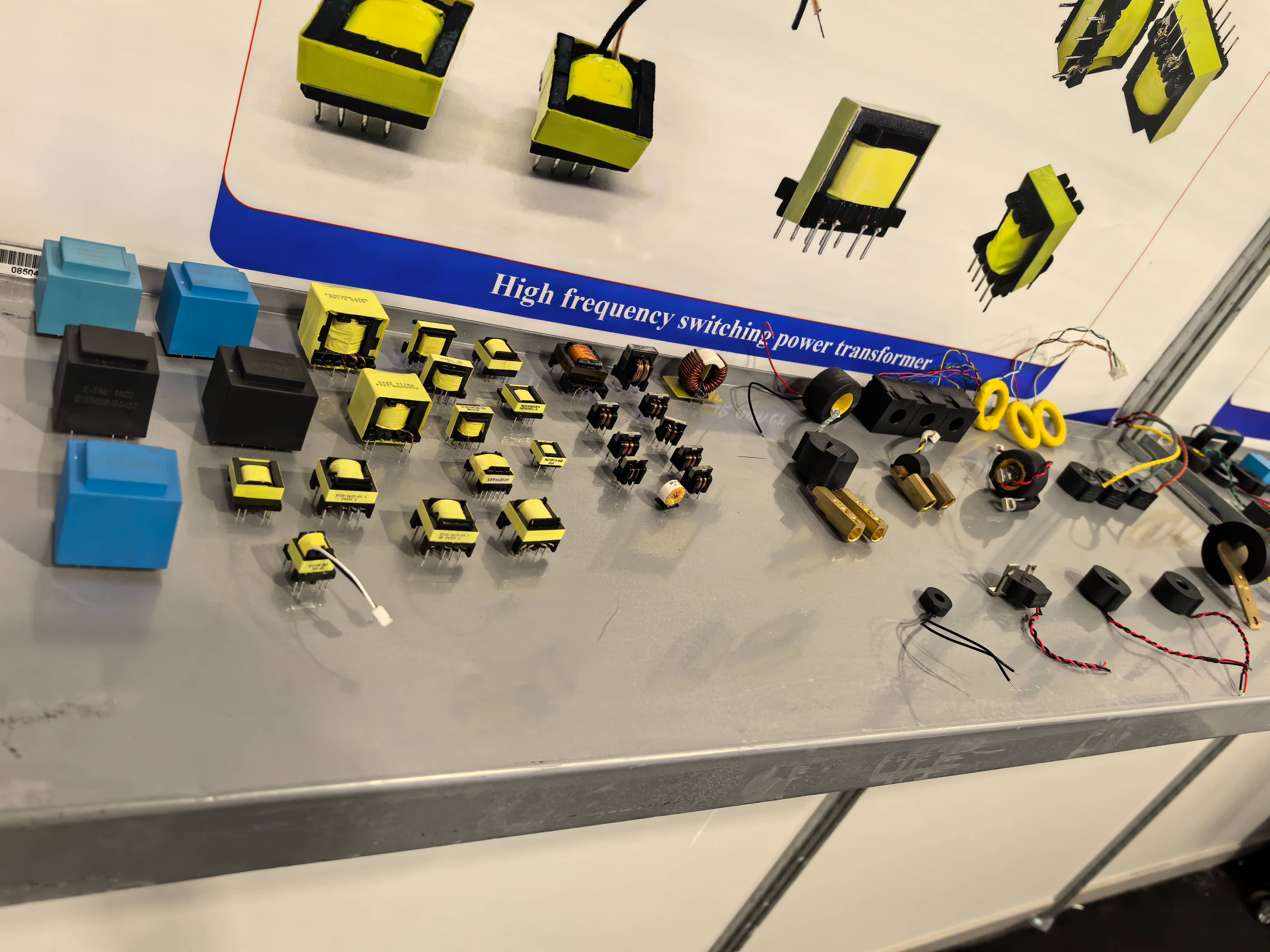

Some projects need custom transformers. You may need a special size, shape, or voltage that standard models do not offer. For example, low-profile systems or unique form factors require custom designs. You might also need unusual winding configurations or special core materials.

| Specification Type | Details |

|---|---|

| Power Ratings | 0.010VA to 30 kVA |

| Unusual Winding Configurations | Yes |

| Frequency Ratings | 20 Hz to 1 MHz |

| UL Insulation System Ratings | 130–220° C |

| Core Shapes | EE, EI, EP, ER, toroidal, etc. |

| Core Materials | Steel, iron powder, nickel, ferrite |

| Custom Tooled Laminations | Yes |

You should talk to a supplier if you need a transformer for a special application. Custom models help you meet your exact needs and keep your system safe.

Choosing the Right Power Transformer Type

Step-Up vs. Step-Down Power Transformer

You need to know the difference between step-up and step-down transformers before you make a choice. Step-up transformers raise the voltage. You find them at power plants and in transmission lines. They help send electricity over long distances with less loss. Step-down transformers lower the voltage. You see them in neighborhoods and buildings. They make electricity safe for homes and businesses.

Here is a table that shows how each type works:

| Transformer Type | Application Role | Voltage Change |

|---|---|---|

| Step-Up | Long-distance transmission | Low to High |

| Step-Down | Local distribution | High to Low |

- Step-up transformers help move power from the plant to the city.

- Step-down transformers make sure you get safe voltage at your wall outlet.

Tip: Always match the transformer type to your system’s voltage needs.

Single-Phase vs. Three-Phase Power Transformer Types

You must pick between single-phase and three-phase transformers based on your building or equipment. Single-phase transformers work best for homes, small shops, and offices. Three-phase transformers fit factories, malls, and large buildings.

| Transformer Type | Typical Use Cases |

|---|---|

| Single-Phase | Residential homes, small businesses, retail shops |

| Three-Phase | Factories, manufacturing plants, large office buildings, shopping malls |

If you run heavy machines or large systems, choose a three-phase transformer. For simple lighting or small appliances, single-phase is enough.

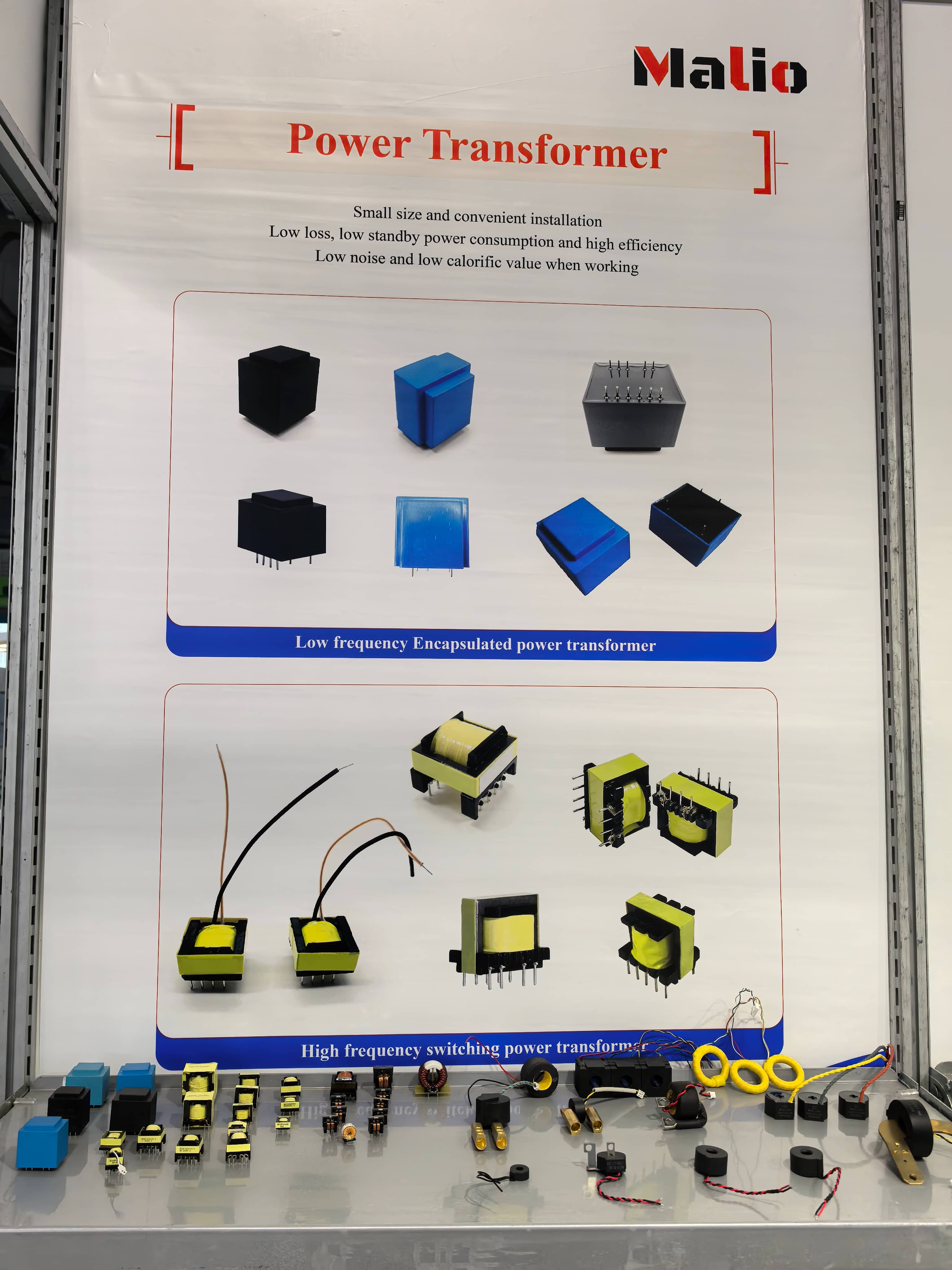

Dry-Type vs. Liquid-Filled Power Transformer

You also need to decide between dry-type and liquid-filled transformers. Dry-type transformers use air to cool the parts. They are safer and need less maintenance. You only need to check them and keep them clean. Liquid-filled transformers use oil or another liquid for cooling. They need more care, like checking liquid levels and testing for gas.

Here is a table to help you compare:

| Aspect | Dry-Type Transformers | Liquid-Filled Transformers |

|---|---|---|

| Efficiency | More efficient, less waste | Can overheat, less efficient |

| Maintenance | Simple checks and cleaning | Needs liquid checks and gas tests |

| Safety | Lower fire risk | Higher fire risk, needs safety steps |

| Recycling | Easier to recycle, less waste | More recycling options for parts |

Note: Dry-type transformers work well indoors or in places with strict fire rules. Liquid-filled types suit outdoor or high-power jobs.

Adding Safety Margin and Planning for Expansion

Importance of Safety Margin in Power Transformer Selection

When you choose a power transformer, you must think about the safety margin. The safety margin gives you extra capacity so your transformer can handle unexpected increases in load. If you skip this step, your system may overload and fail. You protect your equipment and keep your facility running smoothly by adding a safety margin.

Industry standards offer clear guidance. Here is a table showing recommended safety margins for critical projects:

| Source | Recommended Safety Margin |

|---|---|

| IEEE Standards | 25% |

| IEC Guidelines | 20-30% |

| General Recommendation | 15-25% |

Most experts suggest a safety margin between 15% and 25%. For critical infrastructure, IEEE standards recommend a spare capacity of about 25%. Some sources even advise a margin up to 30%. You should always round up your transformer size to include this extra space.

Tip: A safety margin helps your transformer last longer and reduces the risk of overheating or damage during peak times.

Planning for Future Growth

You need to plan for future growth when selecting your transformer. If your business expands or you add new equipment, your power needs will increase. You avoid costly upgrades by thinking ahead.

Experts recommend these steps for smart planning:

- Evaluate your current load and think about possible expansions.

- Prioritize reliability so your operations do not face disruptions.

- Consider smart technology for better efficiency and predictive maintenance.

- Schedule regular maintenance to prevent failures.

You make your system flexible and ready for change by planning for growth. Your transformer will support your needs today and tomorrow. This approach saves you money and keeps your facility safe.

Common Power Transformer Selection Mistakes

Underestimating Power Needs

You might think your current equipment is all you need to consider. Many people make this mistake when choosing a power transformer. If you only look at your present load, you risk running out of capacity as your business grows. For example, a manufacturing plant once picked a transformer based on their immediate needs. Within two years, they had to replace it because their operations expanded quickly. This led to high costs and unexpected downtime. Always plan for future growth. When you select a transformer, add extra capacity so you do not face the same problems.

Ignoring Environmental Conditions

You may overlook the environment where you install your transformer. This can cause serious issues. Environmental factors can affect how well your transformer works and how long it lasts. Here are some common risks:

- High humidity can cause corrosion and insulation breakdown. This increases the chance of electrical failures.

- Dust can build up inside the transformer. This blocks cooling and raises the temperature, which lowers efficiency.

- Vibration puts stress on the parts. Over time, this can damage insulation and other components.

You should always check the site conditions before installation. Pick a transformer designed for your environment to avoid these problems.

Overlooking Safety Standards

You must follow safety standards when you install a transformer. These rules protect people and property. If you ignore them, you increase the risk of fire, electric shock, or equipment failure. Always check local codes and industry guidelines. Make sure your transformer meets all safety requirements. This step keeps your system safe and reliable.

Power Transformer Selection Examples

Residential Power Transformer Scenario

You want to select a power transformer for a small residential building. Start by adding up the total load from all appliances. In this example, the building uses 30 kW. The power factor is 0.9. You need to calculate the transformer size step by step:

- Find the required kVA:

kVA = kW / Power Factor

kVA = 30 / 0.9 = 33.33 kVA - Add a safety margin for future expansion:

Total kVA = 33.33 × 1.2 = 40 kVA

You should choose a transformer rated at least 40 kVA. This size gives you enough capacity for your current needs and room to grow. If you plan to add more appliances or upgrade your home, the extra margin keeps your system safe.

Tip: Always round up to the next standard transformer size. This helps prevent overloads and keeps your equipment running smoothly.

Industrial Power Transformer Scenario

You need a larger transformer for an industrial facility. Factories often use heavy machinery and have higher power demands. Begin by listing all equipment and their power ratings. Suppose your total load is 200 kW, and the power factor is 0.85.

| Step | Calculation | Result |

|---|---|---|

| Find kVA | 200 / 0.85 | 235.29 kVA |

| Add safety margin | 235.29 × 1.25 | 294.11 kVA |

| Choose transformer | Round up to nearest standard size | 300 kVA |

You should select a 300 kVA transformer. This size supports your current operations and allows for future growth. Industrial sites often expand, so planning ahead saves money and avoids downtime.

Power Transformer Quick-Reference Checklist

Selecting a power transformer involves many steps. You can use a checklist to make sure you do not miss anything important. This quick-reference guide helps you review each step before you finish your project.

| Checklist Category | Key Items to Check |

|---|---|

| Electrical Testing | Voltage ratio test, OLTC continuity, exciting current, short circuit test, magnetic balance, tan delta, capacitance, vector group, insulation resistance, polarization index, breakdown voltage, oil moisture |

| Mechanical Inspection | Oil BDV, oil level, clean bushings, remove air, valve installation, breather function, earthing, tighten connections |

| OLTC & Auxiliary Function Checks | Manual and electric OLTC test, alarm and trip circuits, fan operation in both modes |

| Circuit Breaker & Protection Testing | Circuit breaker operation, trip circuit, anti-pumping relay, contact resistance |

| Protection Checks | Protection coordination, relay operation, indication meters, annunciators |

| Defect Reporting | Report any problems or non-conformities before energizing the transformer |

| Standards | Follow IEEE C57.106, IEC 60076-7, IEC 60076-1 |

Tip: Always check both electrical and mechanical parts. A small mistake can lead to big problems later.

You should start with electrical tests. These tests help you find issues with voltage, current, and insulation. Next, inspect the mechanical parts. Make sure oil levels are correct and all connections are tight. Test the OLTC (On-Load Tap Changer) and auxiliary functions to confirm they work in every mode.

Do not forget to check the circuit breaker and protection systems. These keep your equipment safe during faults. Confirm that all relays and meters show the correct status. If you find any defects, report them right away.

⚡ Note: Always follow industry standards like IEEE and IEC. These rules help keep your transformer safe and reliable.

Use this checklist every time you select or install a power transformer. Careful checks help you avoid costly mistakes and keep your system running smoothly.

Selecting a power transformer starts with understanding basic concepts. You need to assess voltage requirements, kVA rating, phase type, and operational frequency. Accurate calculations help you match the transformer to your power needs and prevent overloads. Planning for future growth and considering environmental factors keeps your system safe.

| Why Accurate Planning Matters | Key Benefits |

|---|---|

| Correct load calculation | Prevents overheating and extends lifespan |

| Future growth consideration | Supports long-term performance |

| Environmental awareness | Avoids early failure |

Use the checklist every time you select a transformer. Regular inspections help you spot problems early, meet safety standards, and keep your power system reliable.

FAQ

What is the most important factor when choosing a power transformer?

You must match the transformer’s kVA rating to your load. This step helps you avoid overloads and keeps your equipment safe. Always check your voltage and current needs before you decide.

Can you use a transformer with a higher kVA rating than needed?

Yes, you can use a transformer with a higher kVA rating. This choice gives you extra capacity for future growth. You also reduce the risk of overheating during peak times.

How often should you inspect your power transformer?

You should inspect your transformer at least once a year. Regular checks help you find problems early. Look for oil leaks, loose connections, and signs of overheating.

What safety standards should you follow for transformer installation?

Always follow local codes like the NEC and industry standards such as IEEE and UL. These rules protect people and property. You keep your system safe by meeting these requirements.

Post time: Aug-21-2025