Choosing the right Split Core Current Transformer can make your project safer and more reliable. You face several challenges when picking the best option.

| Challenge | Description |

|---|---|

| Ignoring Accuracy Requirements | Compromising on accuracy can lead to unreliable data, impacting critical decisions. |

| Overlooking Installation Factors | Not accounting for space constraints or cable thickness complicates installation. |

| Choosing Based on Cost Alone | Opting for a cheaper CT can result in poor performance and higher long-term costs. |

You should also check if your low voltage Current transformer fits your needs. Careful selection helps you avoid future problems.

Key Takeaways

- Choose a Split Core Current Transformer that meets your accuracy needs to avoid costly measurement errors.

- Ensure the transformer fits your conductor size to prevent installation issues and maintain accurate readings.

- Select a transformer with a suitable core material for your application to enhance performance and efficiency.

- Always check safety certifications to protect your equipment and ensure compliance with industry standards.

- Plan for installation constraints like space and accessibility to make the process smoother and safer.

Split Core Current Transformer: What You Need to Know

Definition and Function

You use a Split Core Current Transformer to measure electrical current without disconnecting wires. This device has a core that opens, so you can clamp it around a conductor quickly. You do not need to cut power or remove cables. The transformer changes large currents into smaller, safer signals for meters and protection devices.

Here is a table that shows how this device works in electrical systems:

| Feature | Description |

|---|---|

| Design | The core splits or opens, so you install it around a wire easily. |

| Function | It converts high current to a lower, measurable value for monitoring. |

| Applications | You find it in portable meters and low current measuring tools. |

You often use a Split Core Current Transformer in high voltage AC circuits. It helps you monitor AC leakage currents and high harmonic currents. The device also provides isolation and protection for your equipment.

Tip: You can install a split-core transformer without turning off the power. This makes it perfect for upgrades and maintenance.

Benefits for Different Applications

You gain many advantages when you choose a Split Core Current Transformer for your project.

- You save time during installation. The split-core design lets you finish the job quickly.

- You do not interrupt electrical flow. This is important for factories, offices, and homes that need constant power.

- You use the transformer in many places, such as energy management, industrial monitoring, and renewable energy systems.

- You lower costs. You spend less on labor and maintenance because installation is simple.

- You can install split-core transformers without disconnecting power. This makes them ideal for retrofits and upgrades.

- The clamp-on design improves safety and makes adjustments easy. You do not need to cut off grid power.

You see that a Split Core Current Transformer offers flexibility, safety, and efficiency. You can use it in many settings, and you do not face long downtimes or complex installation steps.

Why Choosing the Right Split Core Current Transformer Matters

Ensuring Measurement Accuracy

You need accurate current measurements to manage energy use and costs. If you choose the wrong transformer, you risk getting incorrect readings. Even small errors can affect your energy bills and system checks. For example, phase angle errors in current transformers can distort your energy data. These errors matter most when your system runs at a low power factor. If the phase error is just 6 degrees, your energy measurement can be off by 0.54%. This may not sound like much, but over time, it can lead to big billing mistakes.

| Type of CT | Typical Accuracy Classes |

|---|---|

| Metering CTs | 0.2 or 0.5 |

| Split Core CTs | 1.0 or 3.0 |

| Protection CTs | 1.0 or 5.0 |

You should always check the accuracy class before you buy. Lower numbers mean higher accuracy. For commercial energy monitoring, you often need a class 1.0 or better. This helps you avoid costly errors and keeps your system running smoothly.

Note: Always select a transformer with low phase error for accurate billing and diagnostics.

Maximizing Safety and Reliability

Safety and reliability are top priorities in any electrical project. When you pick the right Split Core Current Transformer, you make your system safer and more dependable. You do not need to disconnect wires during installation, which lowers the risk of electric shock. This design also makes retrofitting easy and quick.

- You save time and money because you do not need to shut down your system.

- The durable build of these transformers means less maintenance over time.

- You can use them in many settings, from factories to office buildings.

| Feature | Split Core Current Transformers | Other Types of Current Transformers |

|---|---|---|

| Installation Ease | Easy installation without disconnecting primary conductor | May require disconnection for installation |

| Accuracy | Maintains reliable performance and delivers accurate results | Varies by type, some may be less accurate |

| Application Suitability | Ideal for retrofit installations | Depends on specific application needs |

You should also look for safety standards like UL 2808 and NEC 2017. These standards make sure your transformer is safe for industrial use. When you choose a reliable transformer, you protect your equipment and your team.

Step-by-Step Guide to Selecting a Split Core Current Transformer

Assessing Your Current Range and Load Requirements

You need to start by understanding the current range and load requirements for your project. This step helps you avoid measurement errors and ensures your Split Core Current Transformer works as expected. For new installations, check the load circuit breaker or the equipment plate. These sources show the maximum and typical amps your system uses. When you know these numbers, you can pick a transformer that matches your needs.

Follow these steps to make the right choice:

- Check if the current transformer output matches your meter or monitoring device.

- Measure the conductor size to make sure it fits through the transformer.

- Find out the maximum and typical amps your load pulls from the power system.

- Look at the accuracy rating to see if it meets your project goals.

If your load changes often, choose a transformer with a wide current sensing range. Make sure the wire size fits the transformer opening. These checks help you avoid installation problems and keep your system running smoothly.

Tip: Always match the transformer size to your conductor and load. This prevents errors and makes installation easier.

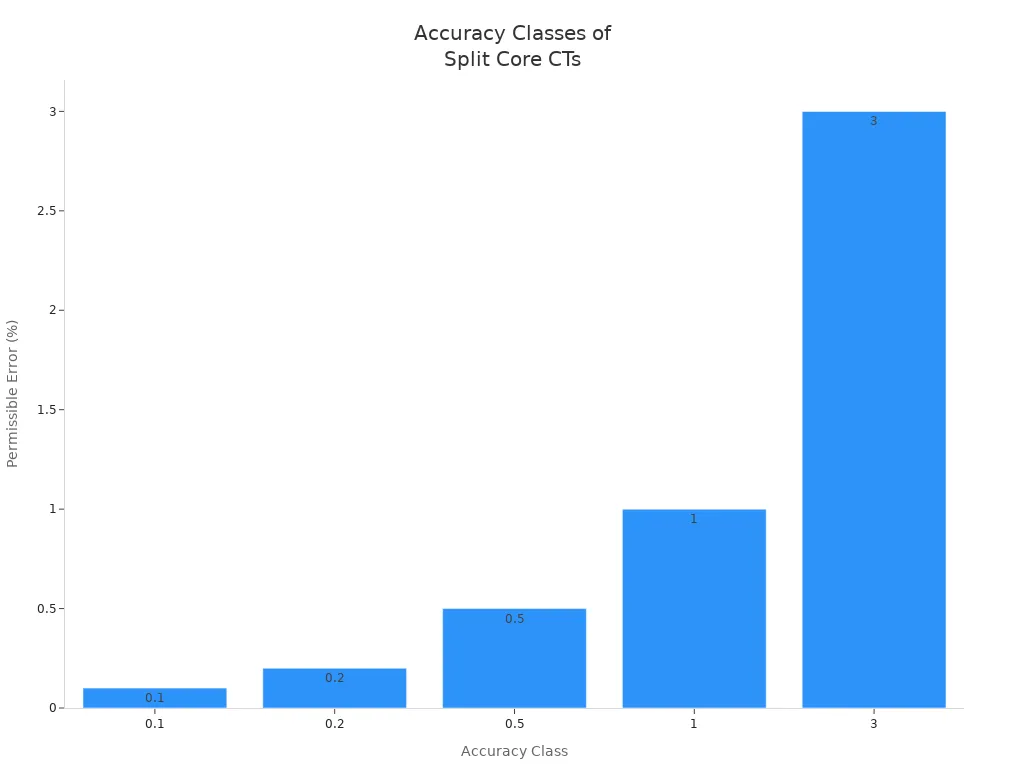

Choosing the Correct Accuracy Class

Accuracy class tells you how close the transformer’s readings are to the real current. You need to pick the right class for your application. If you choose a class with a high error rate, your energy measurements may be wrong. This can cause problems with energy management and billing.

Here is a table that shows different accuracy classes and their uses:

| Accuracy Class | Permissible Error (%) | Typical Use Cases |

|---|---|---|

| 0.1 | 0.1 | High precision applications |

| 0.2 | 0.2 | Industrial metering |

| 0.5 | 0.5 | General monitoring |

| 1 | 1 | Basic applications |

| 3 | 3 | Non-critical uses |

If you use the wrong accuracy class, you may see measurement anomalies. These errors can disrupt energy management and billing. Over time, small mistakes can lead to big financial losses. The accuracy of your energy meter depends on both the meter and the transformer. Standards like IEC/AS set limits for error rates, which help you get reliable results.

- Accurate energy measurement helps you manage energy use and costs.

- Inaccurate readings can cause billing mistakes and waste resources.

- Always check the accuracy class before you buy a transformer.

Evaluating Core Material for Performance

Core material affects how well your Split Core Current Transformer performs. You need to choose the right material for your application. Some materials work better for certain frequencies or loads.

Here is a table that compares common core materials:

| Core Material | Influence on Performance |

|---|---|

| Ferrites | Minimize errors due to magnetic saturation |

| Iron Alloys | Enhance accuracy and linearity |

You can also find silicon steel, nickel-iron alloys, and nanocrystalline cores. Silicon steel works well for power frequency applications. Nickel-iron alloys give better accuracy for a wider range of frequencies. Nanocrystalline cores offer excellent linearity and lower core losses.

Let’s look at the advantages and disadvantages of two popular materials:

| Material | Advantages | Disadvantages |

|---|---|---|

| Silicon Steel | - Excellent magnetic properties - Low cost - High permeability - Suitable for low-frequency applications |

- Higher core losses at high frequencies - Limited efficiency compared to nanocrystalline cores |

| Nanocrystalline Cores | - Exceptional soft magnetic properties - Low core losses - High efficiency at both high and low frequencies |

- Generally higher cost - More complex manufacturing process |

If you want high efficiency and low losses, nanocrystalline cores are a good choice. If you need a budget-friendly option for low-frequency use, silicon steel works well. Always match the core material to your project’s needs for the best results.

Checking Cable and Conductor Compatibility

You need to make sure your cables and conductors fit your Split Core Current Transformer. If you choose the wrong size, you may face installation problems or get inaccurate readings. You should check the following points before you buy:

- The inner diameter of the transformer must be larger than the outside diameter of your load conductor. This helps you install the device easily.

- The opening of the transformer should not be more than twice the wire diameter. This keeps the transformer stable and improves measurement accuracy.

- The current rating of the transformer should meet or exceed the current rating of your load. For example, if your load shows 200 amps, you should select a transformer rated for at least 250 amps.

- You should select the type of transformer based on your installation needs. You can choose from solid-core, split-core, or bus bar types.

Tip: Always measure your conductor before you select a transformer. This step helps you avoid mistakes and saves time during installation.

You can use a table to compare your conductor size and transformer opening:

| Conductor Size (mm) | Transformer Inner Diameter (mm) | Compatible? |

|---|---|---|

| 20 | 25 | Yes |

| 30 | 28 | No |

| 15 | 35 | Yes |

If you follow these steps, you will find a transformer that fits your cables and works well in your system.

Reviewing Safety Standards and Certifications

You need to check safety standards and certifications before you install a Split Core Current Transformer. These standards help you protect your equipment and keep your team safe. You should look for the following certifications:

- TUV Certification: This mark comes from Germany. Many companies in Europe accept it. It shows that your transformer meets strict safety rules.

- IEC60335: This international standard covers home appliance safety. European standards EN60335-1 and EN60335-2 give more details about what you need for safe use.

- EN60950: This European standard covers electrical safety for information products. It also includes GS certification requirements.

Note: Certified transformers help you avoid safety risks and meet legal requirements in many countries.

You should always check the product label and documentation for these certifications. If you see these marks, you know your transformer meets high safety standards.

Common Mistakes When Selecting a Split Core Current Transformer

When you choose a split core current transformer, you want to avoid mistakes that can harm your project. Many people make errors that lead to poor performance, safety risks, or extra costs. You can learn from these common mistakes and make better choices.

| Mistake Description | Impact |

|---|---|

| Incorrect load determination | Causes CT core to be overstretched, reducing device life and distorting measurements. |

| Open circuit conditions | Creates high voltage risks, endangering operators and potentially causing fires. |

| Confusion between protection and measurement CTs | Results in inaccurate current readings and potential damage to measuring devices. |

| Grounding deficiencies | Leads to incorrect current reflection and erroneous relay disconnections. |

Overlooking Current Range Specifications

You need to match the current range of your transformer to your system’s needs. If you select a transformer with the wrong range, you risk overstretching the core. This mistake can shorten the device’s life and cause measurement errors. When the transformer cannot handle the load, it may also create dangerous open circuit conditions. High voltage can build up, which puts you and your equipment at risk. Always check the maximum and minimum current your system uses before you choose a transformer.

Tip: Double-check your load requirements to prevent core saturation and safety hazards.

Ignoring Accuracy Class Importance

You might think all transformers give the same accuracy, but this is not true. If you ignore the accuracy class, your measurements can become unreliable. Inaccurate readings can affect your energy management and billing. Confusing protection CTs with measurement CTs can also cause problems. Protection CTs are not designed for precise measurements. Using the wrong type can damage your meters and lead to costly mistakes. Accurate current readings help you keep your power system stable and safe.

Selecting Incompatible Core Size

You must choose a core size that fits your conductor. If the core is too small, you cannot install the transformer. If it is too large, the device may not measure current correctly. An incompatible core size can also make installation difficult and increase the chance of errors. Grounding problems may occur if the transformer does not fit well, leading to false relay trips or missed faults. Always measure your conductor and compare it to the transformer’s opening before you buy.

Mistakes in selecting split core current transformers can cause errors that affect the accuracy and reliability of your power system. These errors can lead to unstable operations and even accidents. By paying attention to current range, accuracy class, and core size, you help your project succeed and keep your system safe.

Neglecting Installation Constraints

When you choose a split core current transformer, you need to think about installation constraints. Many people forget this step and face problems later. You want your transformer to fit easily and work well in your system. If you ignore installation constraints, you may struggle with tight spaces, awkward cable positions, or even damage to your equipment.

You should check these important installation factors before you buy:

- Space Availability: Make sure you have enough room around the conductor for the transformer to open and close. Crowded panels or tight enclosures can make installation difficult.

- Accessibility: You need to reach the conductor easily. If wires sit behind other equipment or in hard-to-reach places, you may not install the transformer safely.

- Orientation: Some transformers need a specific direction to work correctly. If you install the device upside down or sideways, you may get wrong readings.

- Environmental Conditions: Heat, moisture, and dust can affect transformer performance. You should check if your location meets the device’s requirements.

- Cable Movement: If your cables move or vibrate, the transformer may slip or lose accuracy. Secure the cables before installation.

Tip: Always measure the space and check the environment before you select a transformer. This step helps you avoid costly mistakes and keeps your system safe.

Here is a table to help you remember what to check:

| Constraint | What to Look For |

|---|---|

| Space | Enough room for opening/closing |

| Accessibility | Easy reach to conductor |

| Orientation | Correct alignment |

| Environment | Suitable temperature and humidity |

| Cable Movement | Stable and secure cables |

If you plan ahead and consider these constraints, you make installation faster and safer. You also protect your equipment and ensure accurate measurements. Always think about installation before you buy a split core current transformer.

Installation Tips for Split Core Current Transformers

Preparing for a Safe Installation

You need to prepare carefully before installing a split core current transformer. Safety comes first. Always follow the manufacturer’s instructions for best results. Check that your transformer matches the current and voltage levels in your system. Avoid overloading by monitoring the primary current. Protect the primary side with short-circuit devices. Inspect insulation to prevent electric shock. Never leave the secondary circuit open during operation. Ground the transformer and related equipment to reduce risks. Set up a regular maintenance schedule and calibrate your transformer for accurate readings. Train everyone who works with current transformers on safety practices.

Recommended Safety Steps:

- Follow manufacturer guidelines.

- Verify ratings for current and voltage.

- Monitor primary current to avoid overload.

- Install short-circuit protection.

- Inspect insulation for damage.

- Keep secondary circuits closed during use.

- Ground all equipment properly.

- Maintain and calibrate regularly.

- Train personnel on safe handling.

Tip: Careful preparation helps you avoid hazards like incorrect installation, loose connections, and wiring mistakes.

Ensuring Proper Orientation and Placement

You must install the transformer in the correct position to get accurate readings. Make sure the CT opening is not more than 50% larger than the phase conductor. Place the conductor away from the opening end to reduce magnetic flux leakage. Always follow the mechanical orientation and electrical polarity markings. The arrow or label marked "This side towards source" should face the current source. Connect the white wire to the white dot terminal and the black wire to the black dot terminal. Label all leads to prevent confusion.

| Installation Error | Impact on Accuracy |

|---|---|

| CT not fully closed | Incorrect measurements |

| Wrong polarity connection | Measurement errors |

| Misaligned conductor | Reduced accuracy |

Incorrect orientation can cause measurement errors. Always check alignment and polarity before finishing installation.

Securing Electrical Connections

You need to secure all electrical connections to keep your system safe and reliable. Tighten all terminals to prevent loose connections. Use the correct wire size for each terminal. Double-check wiring against the installation diagram. Label wires clearly to avoid mistakes. If you use multiple transformers, keep each connection organized. Regularly inspect connections for signs of wear or corrosion.

- Tight connections prevent short circuits.

- Correct wiring ensures accurate readings.

- Clear labels help you avoid confusion.

Good electrical connections protect your equipment and help your transformer work as expected.

Testing and Verifying Performance

After you install a split core current transformer, you need to make sure it works as expected. Testing and verifying performance helps you catch problems early and ensures your system stays safe and accurate. You can follow these important steps to check your transformer:

- Ratio Test

You compare the current on the primary side with the current on the secondary side. This test shows if the transformer gives the correct output. If the ratio is off, your readings will not be accurate. - Polarity Test

You check the direction of the windings. This step makes sure the current flows the right way through the transformer. If you connect the polarity wrong, your measurements can be backward or incorrect. - Excitation (Saturation) Test

You increase the voltage and watch when the transformer core starts to saturate. The "knee point" is where the core cannot handle more current. This test helps you know the limits of your transformer. - Insulation Resistance Test

You measure how well the insulation protects the windings. Good insulation keeps you safe from electric shock and prevents short circuits. - Winding Resistance Test

You check the resistance of the transformer windings. If the resistance is too high or too low, the transformer may have a problem inside. - Burden Test

You connect the transformer to its rated load and see if it works under normal conditions. This test shows if the transformer can handle the devices you plan to use.

Tip: Always record your test results. Keeping good records helps you spot changes or problems in the future.

Testing and verifying your split core current transformer gives you confidence in your installation. You protect your equipment and ensure your measurements stay reliable. If you find any issues during these tests, fix them before you use the transformer in your system.

You can choose and install a split core current transformer with confidence when you follow these steps:

- Review your current range and load needs.

- Select the right accuracy class and core material.

- Check cable compatibility and safety certifications.

- Prepare for safe installation and test performance.

Remember: Accurate measurements and safe practices protect your equipment and your team. Use this guide to make smart choices for every project.

FAQ

What is the main advantage of using a split core current transformer?

You can install a split core current transformer without disconnecting wires or shutting off power. This design saves you time and keeps your system running. You also reduce the risk of electrical accidents during installation.

How do you know which accuracy class to choose?

You should check your project’s needs. For billing or energy management, pick a transformer with a low error percentage, like class 0.5 or 1.0. Higher accuracy helps you get reliable measurements and avoid costly mistakes.

Can you use split core current transformers outdoors?

You can use some split core current transformers outdoors if they have weatherproof enclosures. Always check the product’s rating for moisture and dust protection. Look for IP ratings like IP65 or higher for outdoor use.

What happens if you leave the secondary circuit open?

If you leave the secondary circuit open, dangerous high voltage can build up. This can damage your equipment and put you at risk for electric shock. Always keep the secondary circuit closed during operation.

How do you test a split core current transformer after installation?

You can test your transformer by checking the current ratio, verifying polarity, and measuring insulation resistance. Use a meter to compare readings. Record your results to track performance over time.

Post time: Sep-12-2025